PROGLOVE FOR MANUFACTURING INDUSTRIES

SMART SCANNER

FOR YOUR SMART

FACTORY

Integrate your workforce into your digitized supply chain with our wearables and software solutions

PROGLOVE FOR MANUFACTURING INDUSTRIES

SMART SCANNER

FOR YOUR SMART

FACTORY

Integrate your workforce into your digitized supply chain with our wearables and software solutions

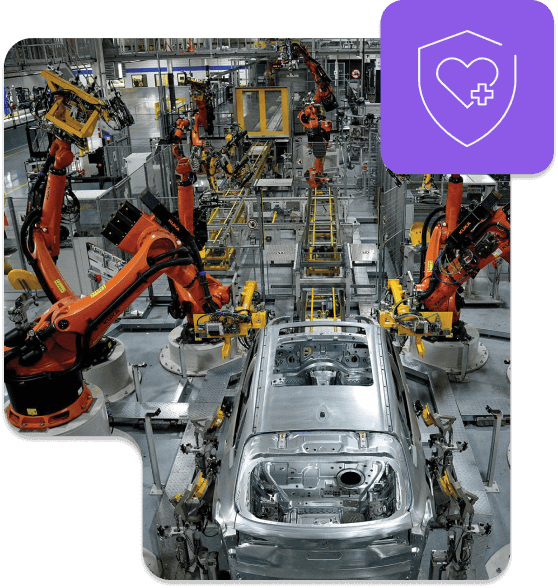

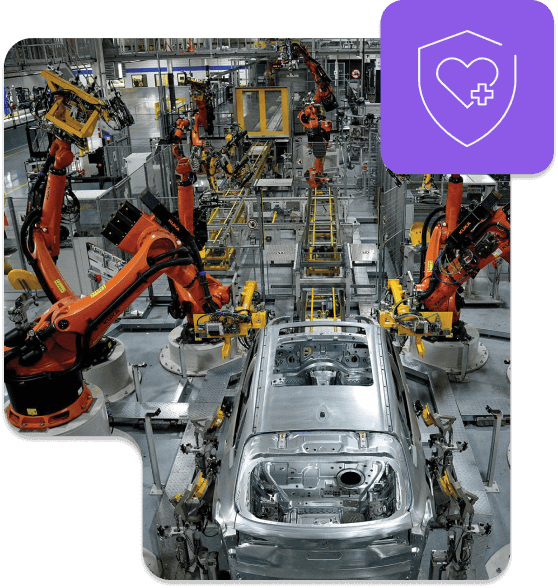

Every second counts while working in small areas with different tools and parts. Whether discrete workstations or at a line, ProGlove assists your operators to work process compliant with the essential information on each assembly task at hand.

OPTIMIZED PRODUCTION PROCESSES

Maintain process accuracy while optimizing your MTM

SEAMESSLY ALTERNATE BETWEEN WORKSTATIONS

The scanner adapts to the process needs

ENABLE A HANDS-FREE WORKFLOW

Safety first-ergonomics with full dexterity