PROGLOVE FOR AUTOMOTIVE INDUSTRIES

PRODUCTIVITY FOR PRODUCTION REDEFINED

Improve your production line efficiency by saving time and preventing errors before they escalate

PROGLOVE FOR AUTOMOTIVE INDUSTRIES

PRODUCTIVITY FOR PRODUCTION REDEFINED

Improve your production line efficiency by saving time and preventing errors before they escalate

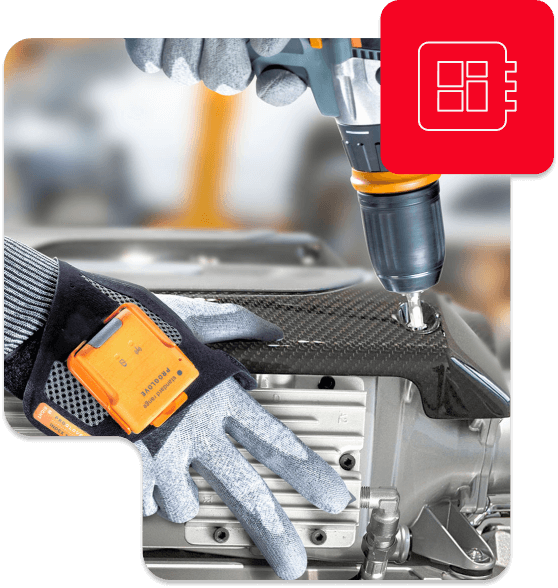

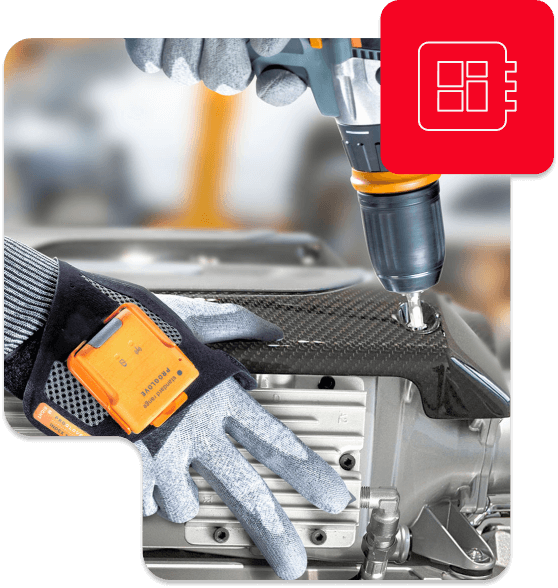

With ProGlove operators can work more ergonomically while scanning parts for quality control and validation during general assembly to match to the car, i.e. brake boosters, cockpit modules, air conditioner parts, and more.

Continuous workflows

Improved process quality with simpler documentation

Optimize mobility for efficiency

Free movement between stations and the plant

Workers hands are always free

Faster, quicker processes with a clear ergonomic value